- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Product

- Solutions

- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Digital Factory

Digital Factory

Enhance total plant

productivity with

IoT condition

monitoring & mobility

Transform data from the shop floor into insights for top floor

Implement data-driven asset performance management

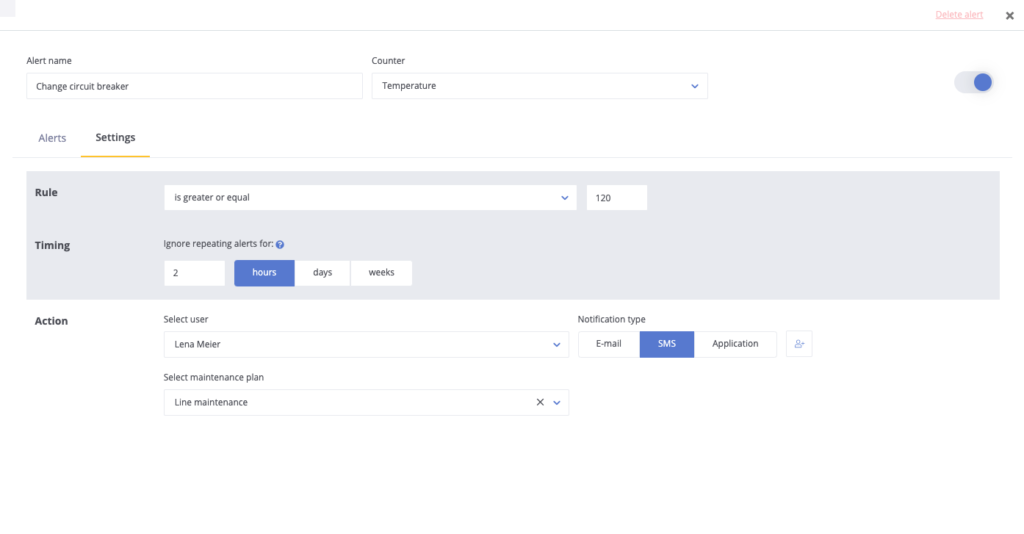

- Real-time condition monitoring: Connect industrial equipment and monitor their health in real-time using Facterra's powerful asset performance management dashboard. Set thresholds and receive notifications via SMS, email, or in-app alerts when anomalies are detected in your manufacturing facility.

- Predictive maintenance: Harness the power of historical metering and sensor data to create and implement advanced predictive maintenance algorithms, elevating performance management for crucial assets in your manufacturing operations.

- Single source of truth: Facterra, the leading EAM software, hosts all critical asset operation data and KPIs for industrial facilities, providing secure access to a wide range of users. Grant protected access to suppliers, service providers, maintenance technicians, and customers as needed, ensuring a centralized and reliable data source for your enterprise asset management needs.

Digitalise safety & regulatory compliance

- Digital operations: Digitize operator training using rich media and Facterra's robust EAM platform. Implement digital standard operating procedure (SOP) checklists, ensuring the latest versions are always available for workers in your manufacturing facility.

- Regulatory compliance: Utilize Facterra's integrated asset historian to demonstrate compliance with safety and hygiene regulations through a fully searchable audit trail. Achieve a paperless plant and streamline your industrial asset management.

- Digital shift logs: Engage frontline workers with relevant and targeted announcements using Facterra's built-in communication capabilities. Efficiently deploy new safety and hygiene procedures or announce your employee of the month, ensuring all users are notified within minutes in your manufacturing operations.

Best in class cloud capabilities

- Reliable & secure: Facterra's Cloud solution comes with security built into its architecture and our core processes. We guarantee high-speed, accurate data storage and complete data availability at all times.

- Integration: The Facterra Cloud solution is open to integrate with a wide range of IT, MES & SCADA systems. We make it easy for you to have a single system of your choice from where you can monitor your asset and operational processes.

- Future-proof and scalable: From small businesses who only need one simple dashboard now or know they'll want to upgrade to more complex technology in the near future to massive multinational corporations that require immediate data insights from several devices. A platform that is ready to use right away, with all of the capabilities needed to scale up for a bright future with Facterra.

How it helps?

Manage maintenance

Manage preventive maintenance from any device

Report tasks

Technicians and production managers can easily report tasks that need to be addressed through work requests directly from the landing page

Manage tasks easily

Checkboxes make signalling and listing tasks much easier

Save time

Saving time thanks to a tool that makes collaboration between teams much more fluid thanks to the Kanban listing all the maintenance activities of the company.

Manage activities

Easy scheduling and closing of maintenance activities

Analyze performance

Easy analysis of the status evolution and performance of each equipment thanks to equipment analytics

Impact you get using Facterra

15%

Higher asset availability

Improvement in maintenance performance (MTTR & MTBF)

20%

Higher energy efficiency

20% reduction in electricity consumption in standby mode

10%

Leaner parts inventory

Improvement in spare parts inventory stock turn

35%

Time saved on audits

Simplified compliance with an easily searchable, digital audit trail.

Prairie Aquatech

Download Case StudySend download link to:

The experience with Facterra is very good. From my point of view, it couldn't be better. Support is great, they respond to our wishes, even with suggestions for improvement. I think that's also very good. Such a company you don’t find easily!

Jörn Möller

Leiter technische Werkstatt

Molkerei Rücker

The experience with Facterra is very good. From my point of view, it couldn't be better. Support is great, they respond to our wishes, even with suggestions for improvement. I think that's also very good. Such a company you don’t find easily!

Jörn Möller

Leiter technische Werkstatt

Molkerei Rücker

The experience with Facterra is very good. From my point of view, it couldn't be better. Support is great, they respond to our wishes, even with suggestions for improvement. I think that's also very good. Such a company you don’t find easily!

Jörn Möller

Leiter technische Werkstatt

Molkerei Rücker

Trusted by companies

across 3 continents.We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.To find out more about the cookies we use, see our Privacy Policy

If you decline, your information won’t be tracked when you visit this website. A single cookie will be used in your browser to remember your preference not to be tracked.

Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. - Digital Factory