- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Product

- Solutions

- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Digital Factory

Facterra in Detail

Make the most of

your equipment

with Facterra

Facterra is an asset performance management software that enables you to bring your machines to life! It has been specially designed to give you a holistic view of your plant’s activities and to facilitate the daily actions of your employees. A proven time saver for a more efficient monitoring of activities. With the ability to exchange and receive information such as documentation or spare parts lists directly from your suppliers, this is THE software that will help you optimize your plant.

Maintenance at the

heart of your activitiesMaintenance is at the heart of a plant’s life. Good maintenance of equipment is essential to its proper functioning.

Facterra is a designer tool to meet the need for planning and monitoring of these maintenance activities.

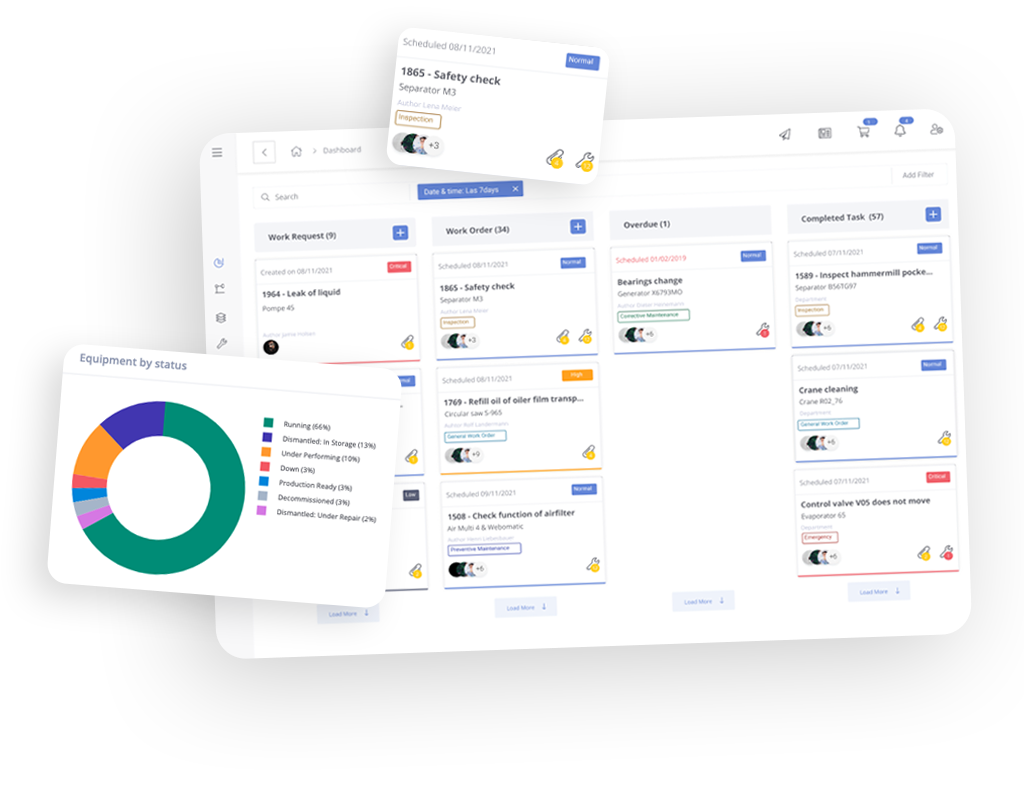

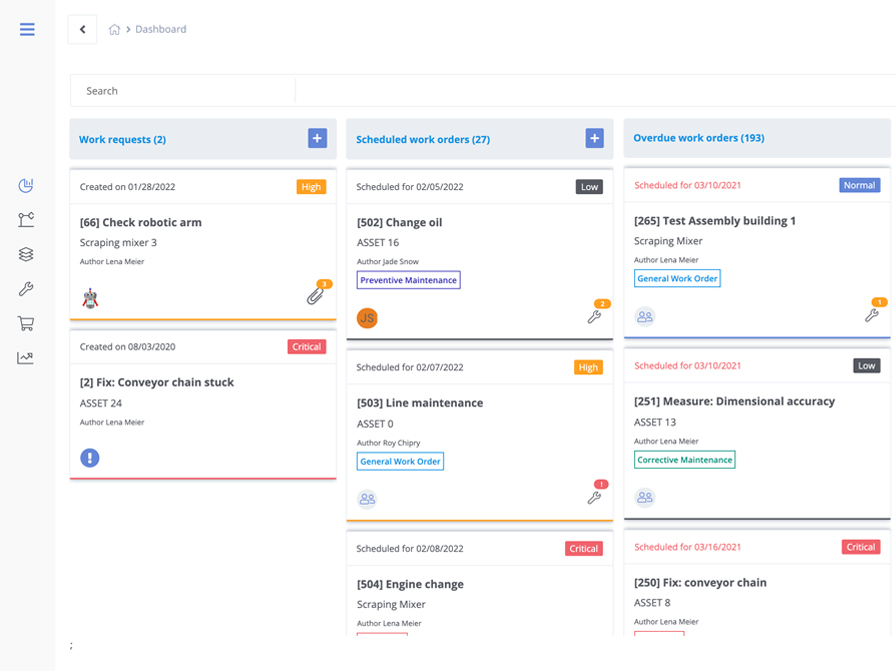

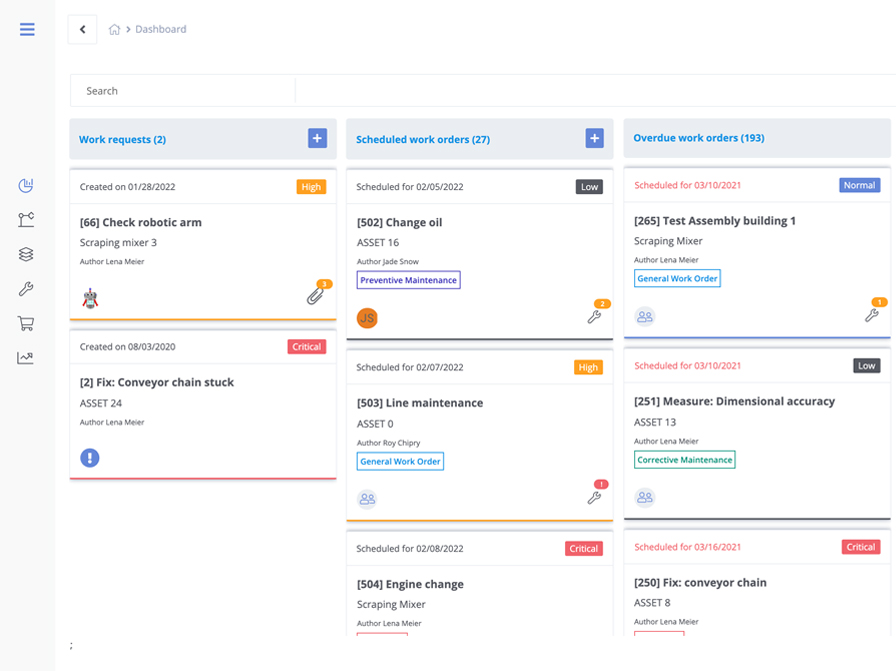

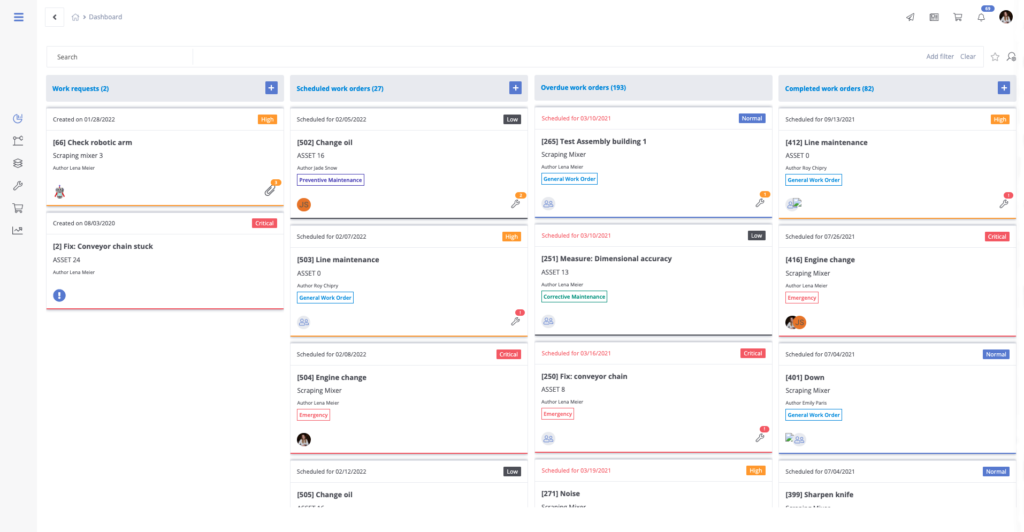

Maintenance is at the heart of our asset performance management tool. Keeping this in mind, Facterra offers a 4-column dashboard allowing you to have an overview of all upcoming, ongoing and completed maintenance activities at a glance.

Organized into work requests, work orders, overdue work orders and completed work orders, the dashboard allows you to plan your daily activities in a few clicks and drag and drop without getting lost in a multitude of tabs.

All information related to maintenance can of course be found in the dedicated section.

You will find the list of work requests and work orders, but also the maintenance plans.These plans are a template of maintenance activities that you can apply to equipment or collections of equipment according to a recurrence that you define. Come and create your own maintenance plans and apply your own recurrence rules!

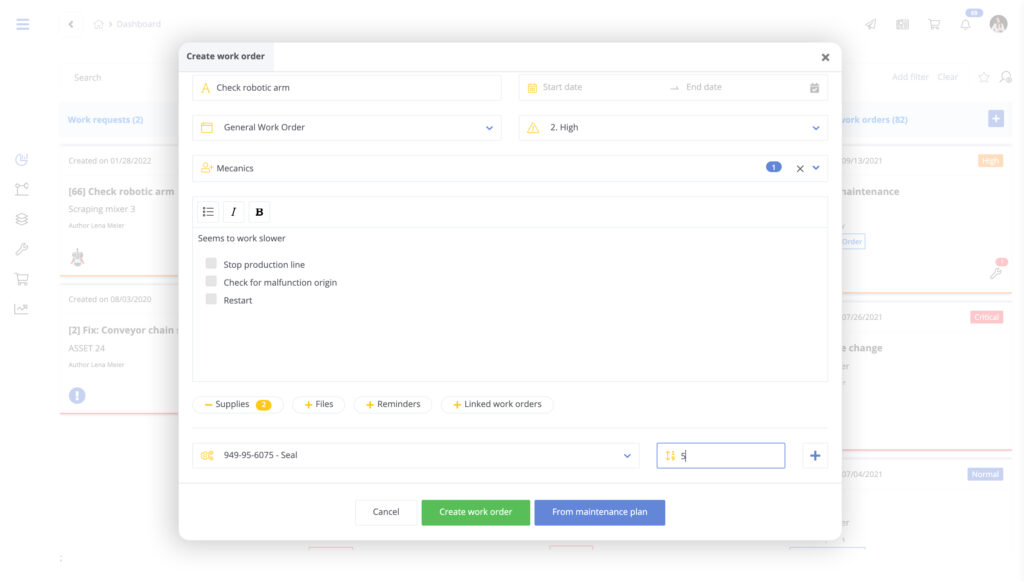

Optimize your time and maximize your performance! When you create a work order, you have the possibility to add and link various elements such as documents and photos or spare parts. These elements are directly taken into account in all the sections concerned and save you unnecessary trips between the different parts of the tool.

For example, when you link spare parts to a work order, you will be asked to indicate the exact quantity used when you complete it. This way, the inventory will be automatically updated.

A vision centered around your equipment

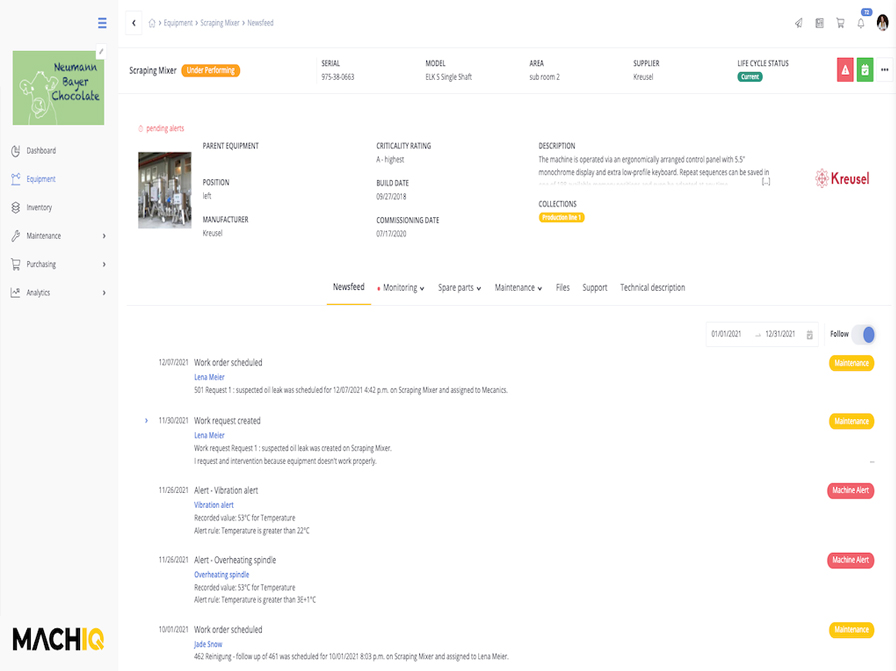

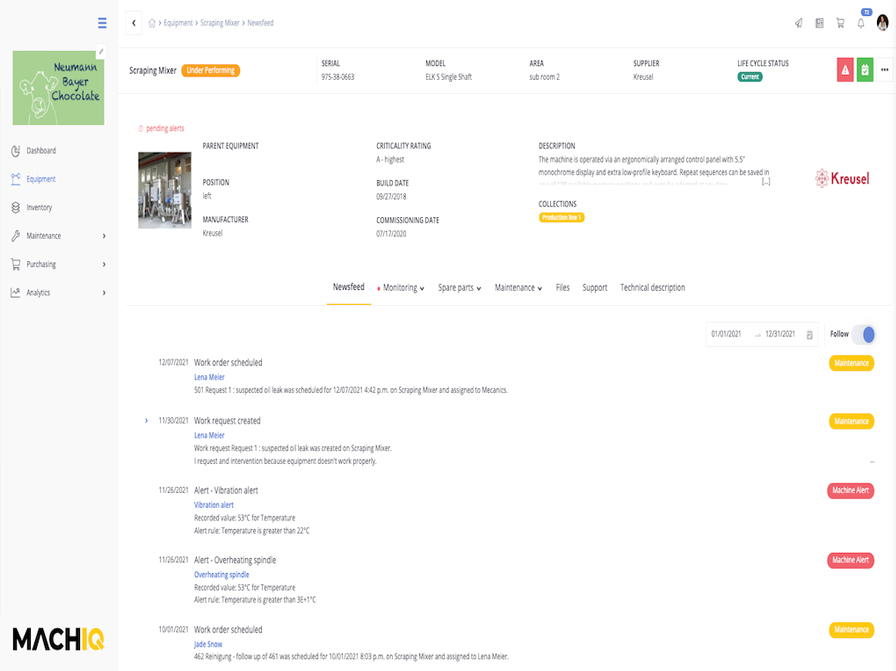

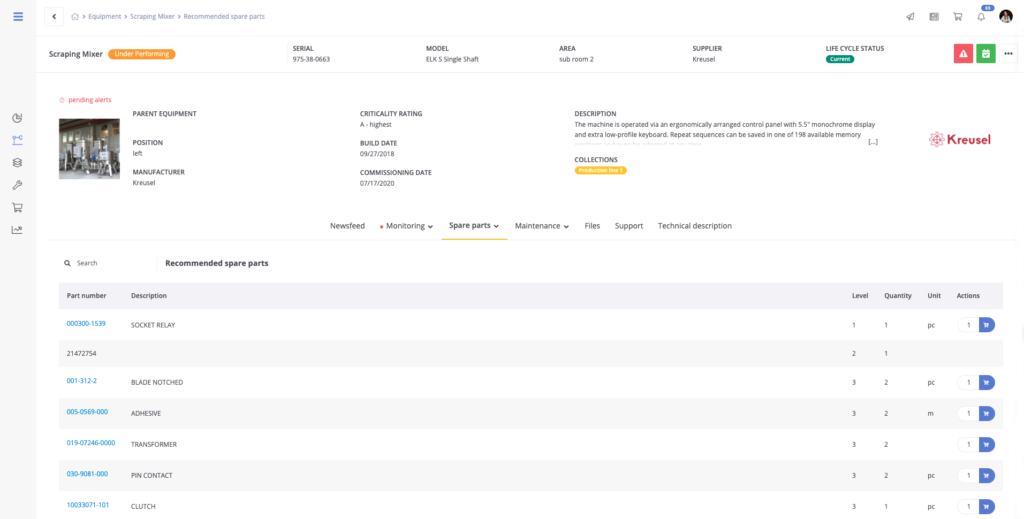

The Equipment section is designed to allow you to centrally manage all your equipment from a single list.

Here you will find a list of all your equipment and can see the maintenance activities assigned to them as well as analyze their performance and find related documentation.

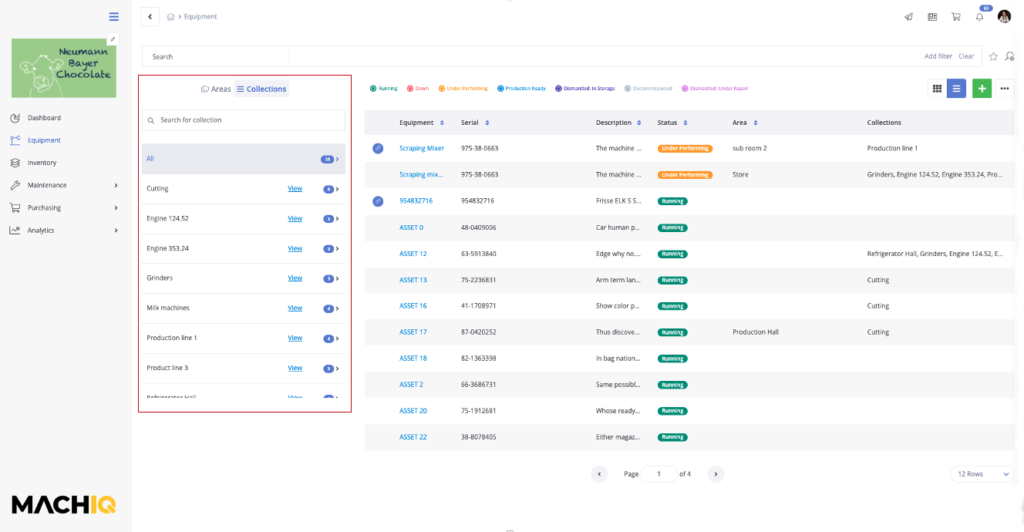

To facilitate your organization it is possible to group equipment into different areas and collections.

The area includes a physical dimension. For example, you can group equipment stored in the same hall into the same area. A piece of equipment can only be located in one area.

On the other hand, a collection is a grouping of equipment according to a user-defined factor. You can therefore group equipment according to the spare parts used. The same equipment can therefore be found in several collections at the same time.

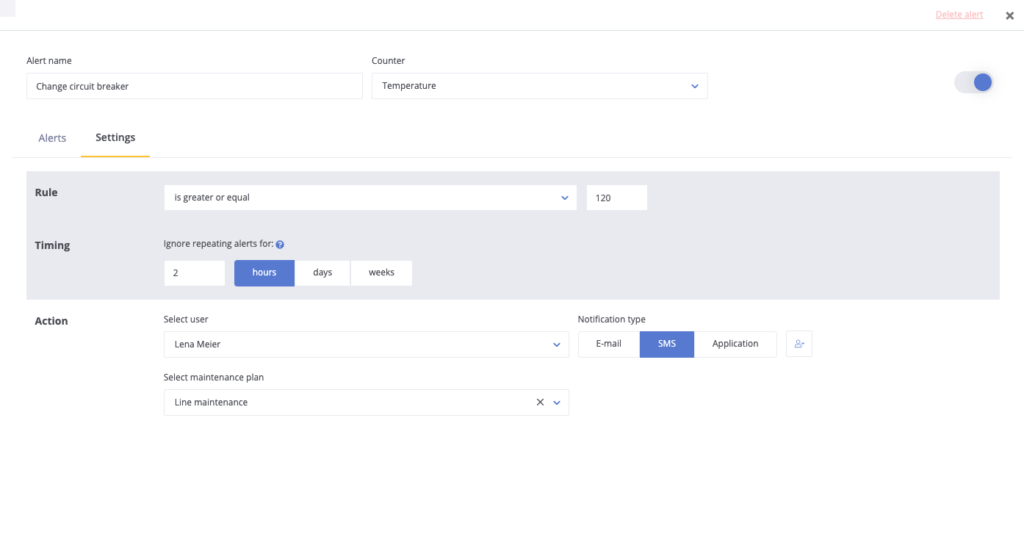

Your equipment is certainly equipped with meters. These can be recorded directly on the equipment and updated directly from the page or when closing the work orders.

You can also set up an alert system linked to the counters that will allow you to plan maintenance actions as soon as the alerts are triggered.

At Facterra we find sharing information particularly important to make your job easier. Save time with information directly from your suppliers. On the equipment page you can request and have direct access to shared documentation, as well as lists of recommended spare parts for your equipment.

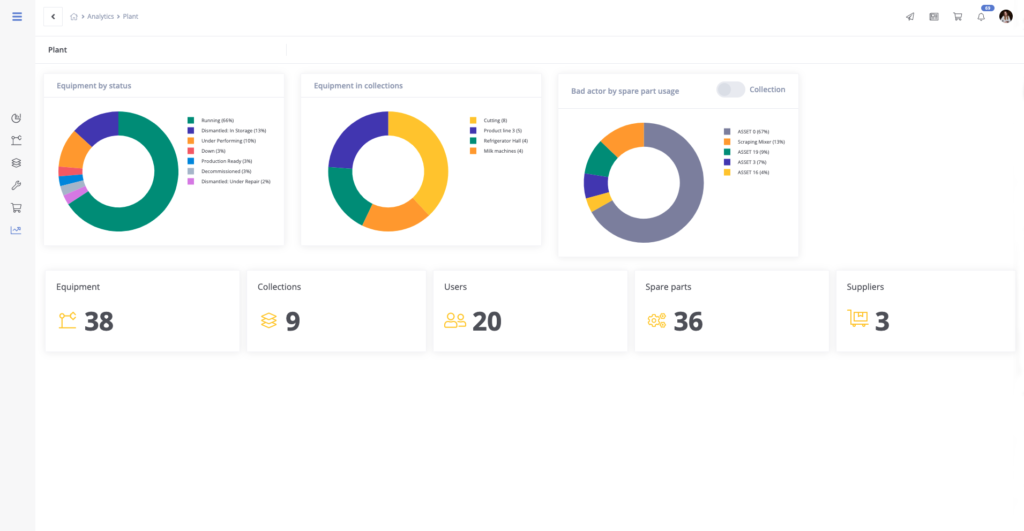

An important part of the tool is also the ability to analyze the performance of your equipment.

For example, when you link spare parts to a work You also receive alerts for each entity, a fully customizable dashboard is provided in which you can choose exactly the Key Performance Indexes you want to analyze. A section dedicated to the analysis of the general performance of the plant is also available.

Interested in learning more?

Don’t wait any longerWe use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.To find out more about the cookies we use, see our Privacy Policy

If you decline, your information won’t be tracked when you visit this website. A single cookie will be used in your browser to remember your preference not to be tracked.

Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. - Digital Factory