- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Product

- Solutions

- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Digital Factory

Monetization strategies for smart services

This is the second in a 3-post article series on Smart Services. You can read the first article on building a strong business case here.

A challenge that a lot of machinery companies that we speak to are struggling with, is finding the right monetisation model for their smart services. A recent Copperberg article also dealt with the challenges of monetisation that industrials face – particularly in bundling and unbundling service products. Many have kicked the can down the road by adopting “freemium” pricing plans where 100% of their customers are still on the free plan. While the adoption numbers can look great, mostly-free freemium service products eventually suffer from low follow-on investments that result in a rapid slide to the irrelevance of “archived offers”. In this article I explore the available pricing options that I have seen succeed, even if only partially so.

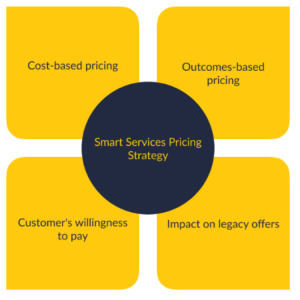

A good monetisation strategy takes into account the following factors:

- Fixed and variable costs incurred to develop and deliver the service respectively

- The unit of value that is delivered to the customer that can be measured & monetised

- The willingness of the customer to pay for this unit of value

Let’s explore how each of these contribute to building a successful smart service business.

The fixed and variable costs to build and deliver smart services

Most machinery OEMs who are taking their first steps into the digital world are used to selling hardware as a one time transaction. Even the services that they sell thereafter are primarily transactional in nature – spare parts, repair services, etc. What this results in is a pricing culture that maximises upfront payments and one-time revenue events. Smart services not only involve sensors and data collection/transmission hardware like historians and internet gateways, they also incur recurring costs related to networks, cloud infrastructure for data collection and analysis. While such costs appear minuscule in the beginning and during pilot trials, they can represent a substantial proportion of the overall cost of delivering the service. Additionally, most OEM’s also ignore the cost of supporting customers since they don’t have any experience with such services. Users expect supplier support for all kinds of issues from password resets, to data restoration following accidental deletions, to more advanced situations when there are actual emergencies with their machines. All of these require a support team being available at call to customers. This usually tends to be the biggest cost that most first-time smart service products miss and it can cost a lot. The biggest mindset change that contributes to a profitable smart service offer is the acceptance that upfront hardware costs should be amortised over the entire period of the service contract and shouldn’t be the source of margins. Provided the recurring charges are not too expensive, the real margins kick in once the cost of sale has been covered.

Outcomes-based pricing based on a unit of delivered value

I have written about a value-driven business case for smart services here. The most powerful but also the most risky pricing model is one that assures a specific outcome. Your marketing material might promise higher uptime or lower defects but can you put some skin in the game? Can you offer to get paid based on how successfully you deliver the promised outcome? If you answered yes, you should simply price your service based on a % of the $ value your outcome delivers to your customer. Typically, your CFO organisation will need to work with insurance partners to under-write the risk that you are taking but if you nail the execution, you are likely sitting on a gold-mine.

That said, I am also a big fan of Freemium pricing models where while the initial adoption has minimal friction, as the value delivered to the customer increases, the customer is forced to pay for the service. However, freemium pricing models must ensure that there is a clear path to future revenue, i.e. a paid subscription as the customers’ usage of the service increases.

Depending on how hard it is to extract the same value by adopting alternatives, OEMs can get away with pricing the service at upto 30% of the value captured for the customer. However, an internal challenge will be to get IT-teams to support such pricing models because your traditional ERP system was built before a time when such payment models were conceived and it is likely going to be a big drag on your speed to deploy. In either case, you should give us a call. Seva, while not an ERP system per se, is designed to support such business models.The customer’s willingness to pay

Such innovative business models don’t often get enthusiastic receptions from customers. Manufacturing is a traditional and very conservative segment. Variance of billing is usually something most companies get very uncomfortable with. This is where tiered pricing plans come into play, putting a ceiling on how much a customer might be liable to pay in any year. Predictability is usually a BIGGER factor than the actual price for most customers. Another factor that plays a significant role especially for subscription purchases vs. one-time purchases is whether there is On-going value being delivered or if the value delivered is a one time affair – at the time of sale. Most performance improvements happen in the first 6-12 months of adoption (longer time frames are very suspect in my opinion). If the continued use of the service doesn’t either improve performance further in visible ways or serve to retain the performance gains, then there is little or no incentive to subscribe vs. just pay for the service as a one time purchase. A good example we have seen from a Seva customer who is offering Condition-Based Maintenance SLA’s that go far-beyond traditional preventive maintenance/service SLA’s. In their case, they offer to continuously optimise spare parts utilization and inventory, thus saving cost as well as freeing up operating cash. The performance of this service is contingent on monitoring the evolving health of the machines they monitor and therefore the value is delivered in an ongoing manner, far beyond the initial efficiency gains.

[And a 4th bonus factor that makes or breaks the sales thereafter] Does such an offer cannibalise other, more successful revenue streams

Most product managers ignore the impact that their service may have on their own revenue streams. Will it result in lower sales of spare parts? Fewer paid service visits? Usually smart services start small – with fewer customers and very little ARPU (Average Revenue per Unit). If they appear to threaten the more well-entrenched and high revenue services of the machine builder, they are likely to fail because the salesforce, which is incentivised on revenues and not margins, would rather promote the high revenue service offers. A more holistic narrative is necessary to achieve initial revenue traction with the support of the salesforce. In order to bring them to enthusiastically support such services, the compensation from revenue gained vs. revenue lost must be easy to demonstrate. At the very least, smart services should address some of the pain points that the sales teams themselves have with the existing services – whether resulting in fewer customer complaints or a more hassle-free selling experience for the sales teams. Machinery companies that use Seva have the advantage of viewing not just their service relationship with their clients in terms of relationship value but also the operational activities incurred in delivering these services. This makes it easier to pick the customers for whom such services will be attractive as well as profitable for themselves. More on this topic in my next and final post on this series on smart services.

PREV

The Product Manager’s guide for Smart Services (Part 1)

NEXT

Selling smart services and scaling the business (Part 3)

Related Posts

The Manifesto for a New Normal

It was exactly a year ago that I returned from BrauBeviale, an international trade fair for the beverages and brewing industry and realised that I had lost my sense of taste. It was still pre-Covid-19 in the news, my doctors put it down to an inexplicable neurological cause that they couldn’t diagnose.

November 19, 2020

The long-tail is where the next billion in service revenue is (Part 2)

In my last post, I covered the stakes in expanding

August 10, 2020

Get Started

Interested in evaluating the

product for your team ?We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.To find out more about the cookies we use, see our Privacy Policy

If you decline, your information won’t be tracked when you visit this website. A single cookie will be used in your browser to remember your preference not to be tracked.

Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. - Digital Factory