- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Product

- Solutions

- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Digital Factory

The Covid-19 lockdowns have been brutal on supply chain. In Europe, closed borders have resulted in longer lines at border-crossings than many of us have seen in decades. Many senior executives that I spoke to, have confided to me about their challenges in keeping their operations running when they are running short of critical spare parts and supplies. Business models that had been built around cash-efficient Just-in-time models have broken down or have been severely stretched as a result of supply-chain disruptions. We foresee a shift from just-in-time to just-in-case buying for spare parts and supplies. In this post, I will focus on some of the things we are doing at Facterra to help our machinery customers adapt to the changes in customer behaviour.

In the best of times, executing a cashflow-efficient spare parts business has the challenge of anticipating customer demand. Without access to customers’ spare-parts inventory levels in real-time, every customer purchase order is a balancing act, between optimising pricing, availability, shipping methods and costs while managing customer satisfaction at acceptable levels. The Covid-19 lockdown and the reopening is showing machinery companies everywhere that historic data is no indicator of future demand. Demand models built on historic annual cycles have broken down during the lockdown. They will break down even further as customers stock up with a vengeance to prepare for potential disruptions from potential Confinement 2.0’s and Trade Wars X.0.

It is increasingly clear that most suppliers will not be able to produce parts fast enough to keep up with demand spikes. This is due to their own supply chains also being intensely strained by the current situation, and the social distancing measures implemented in their own production plants. At the other extreme is the risk that suppliers may build up stock for items based on the demand spike and then the demand suddenly falls off a cliff. (To illustrate my point, you’d only have to look at the pile of pasta and tomato cans that you bought at the beginning of the lockdown that you haven’t consumed yet). To clearly articulate the challenge ahead, it is: How can machinery companies and OEMs offer availability assurance for spare parts without pricing themselves out of the market and without risking over-stocking on parts for a demand that may not materialise?

Consignment stocks services

Some machinery companies already offer consignment stock contracts. These contracts enable them to maintain a safety stock of critical spare parts, often at their customers’ sites. The benefit for customers is that the suppliers absorb the cash impact of maintaining inventories and only pay for parts when the consume them. While this is great for customer retention, the resulting cash inefficiency on the suppliers makes such contracts expensive and unpopular with CFO’s. We see emerging digital technologies being able to play a bigger role in making such contracts much more cash efficient for suppliers.

Towards more collaborative spare parts logistics models

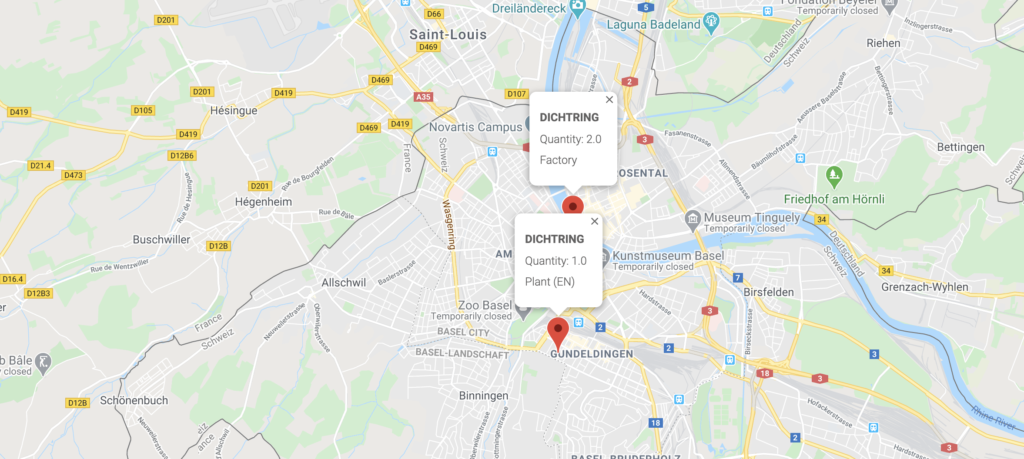

Connected Inventories: Vendor managed inventories aggregating multiple customer stocks Many suppliers adopt defensive strategies like obscuring OEM references. The goal here was to prevent customers from ordering parts directly from the original manufacturer. In the era of 3D printing and emerging data standards like eCl@ss and ETIM, these practices will not be sustainable. Instead, we believe that vendor managed inventory (VMI) with Availability Service Contracts is a much more defensible, win-win business model for the future. It can be deployed at scale in the process industry, implementing digital technologies. Aggregating spare parts inventory data from multiple customer sites in a region is now technically feasible on systems like Facterra's Seva. Doing so would also achieve two significant benefits for suppliers over traditional VMI service models.

- Achieve lower costs for both customers and suppliers

- Enable machinery companies to serve more customers

Having permanent visibility of customer inventory levels and aggregating such data with the supplier inventory enables machinery OEMs to merge the best of both “Just in time” and “Just in case”. They can design inventory strategies based on algorithms that take in to account historic demand and remote condition monitoring data that gives helps them anticipate failures that may necessitate parts replacements. But there is a bigger opportunity that remains untapped. What if the excess and often obsolete parts in the inventory of one customer can actually enable another customer to run their machines for longer? During recessions, such services will not only be appreciated by customers but will even generate additional cash with minimal investments for OEMs.

For OEMs to make such a transformation however will not not be simple, it will need a profound mindset shift. OEM’s will need to see themselves as orchestrators of equipment uptime for their customers instead of mere suppliers of parts. Are they ready for such a transformation? Some definitely are, and we have the most innovative among them driving our product development efforts on Seva.

PREV

5 tips for getting spare parts e-commerce right

NEXT

Field Services is dead. Long live (digital) field services

Related Posts

The Product Manager’s guide for Smart Services (Part2)

This is the second in a 3-post article series on Smart Services. You can read the first article on building a strong business case here.

May 27, 2021

The long-tail is where the next billion in service revenue is (Part 1)

For the last couple of decades, as service revenue grew in importance

July 24, 2020

Get Started

Interested in evaluating the

product for your team ?We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.To find out more about the cookies we use, see our Privacy Policy

If you decline, your information won’t be tracked when you visit this website. A single cookie will be used in your browser to remember your preference not to be tracked.

Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. - Digital Factory